How to glue your DIY Mattress?

What you will need:

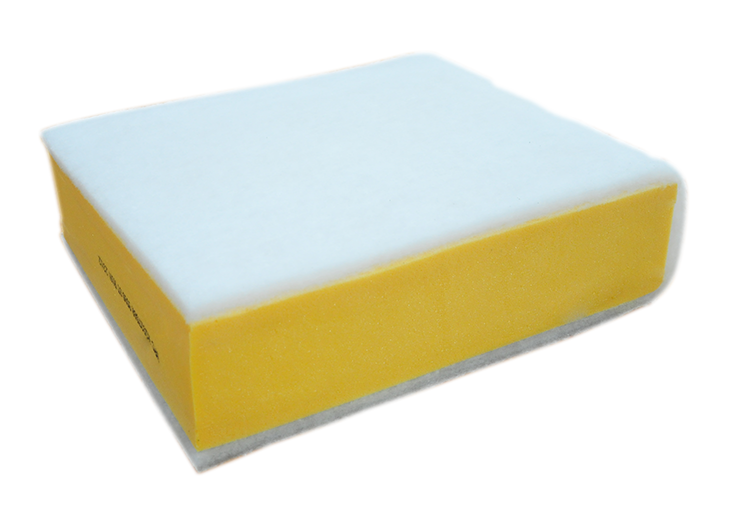

- Your pre-cut pieces of foam from our custom cut section

- All-purpose glue from our craft section

- A mattress cover from our Sleep Accessory section

- A protective cover under the foam you are gluing (craft paper, plastic or a tarp.)

Step 1.

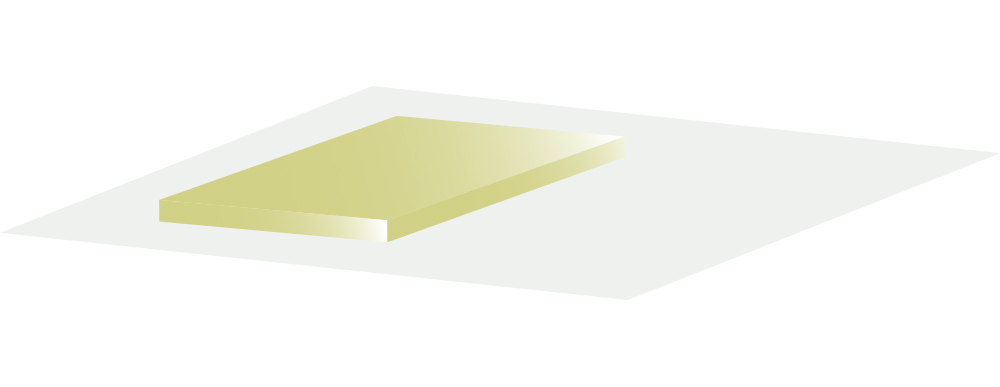

- Lay your protective covering down; it must be larger than the mattress to protect your work surface from glue overspray.

Step 2.

- Lay your mattress core on top of the protective cover.

Step 3.

Step 3.

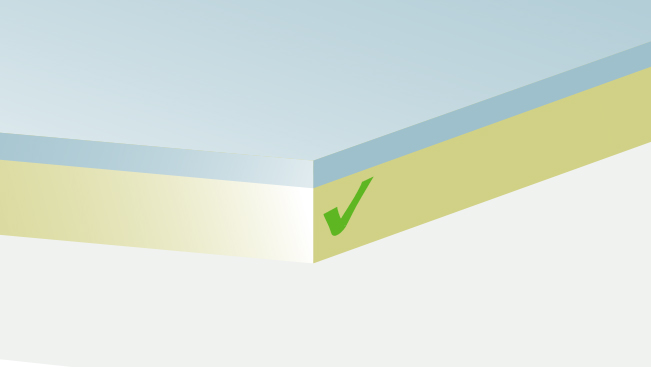

- Get the next layer you are gluing to the core and put it on top of the core to ensure you have a good fit.

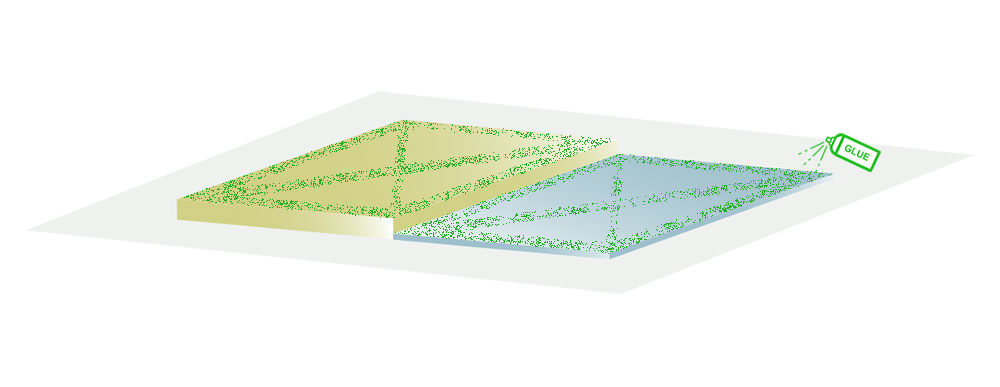

Step 4.

- Spray glue on the perimeter of both the core and the next piece as well as a full X on each piece.

Step 5.

- Lay the glued sides together ensuring they are perfectly lined up so you do not have bulges when you zip you cover on.

Step 6.

- Press the perimeter and the centre of the mattress (laying on it too) to ensure the glue has contact on both sides.

Step 7.

- Provide sufficient time for the glue to dry (minimum 5 min).

Step 8.

- Repeat steps 3-8 if you are adding additional layers.

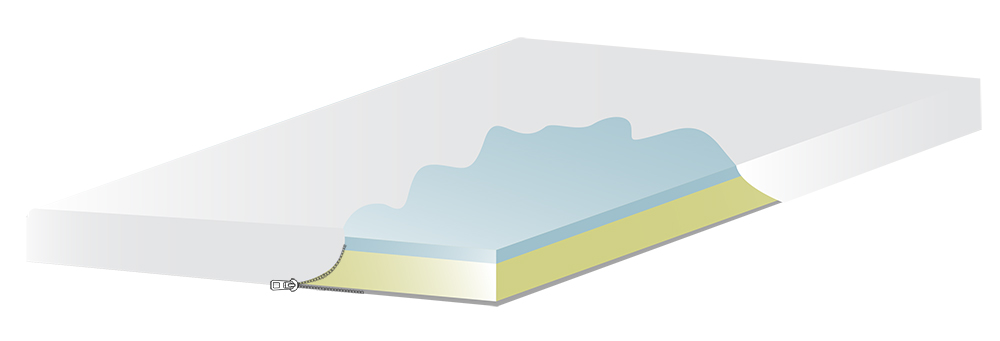

Step 9.

- Unzip cover, lay the bottom part or the cover down and set the assembled foam mattress on top of it, ensure it is square.

Step 10.

- Let the top side of the cover on square…..zip it together.

Step 11.

- Set the mattress on the suitable foundation (see our foundation section) to support the full mattress.

Step 12.

- Enjoy your sleep!